Sykes Innovation

Sykes are committed to a path of innovation for the future. We spend every day striving to improve so as to translate every ounce of your effort into output; removing wastage and increasing speed. Having been innovating for over 50 years, we have an impressive list of world firsts in everything from hull design to permanent seat ties and even drink bottle holders.

Below is a sample of our recent innovations.

Bow Ball: 2017

Sykes has reduced the freeboard (height from waterline to top of the deck) in our new fifth generation boats to improve handling in crosswinds and choppy water. Less boat above the water has allowed us to redistribute weight to other areas of the structure to improve stiffness and overall performance.

Sykes has reduced the freeboard (height from waterline to top of the deck) in our new fifth generation boats to improve handling in crosswinds and choppy water. Less boat above the water has allowed us to redistribute weight to other areas of the structure to improve stiffness and overall performance.

The bow ball in our single sculls has been lifted to keep it clear of the water in all conditions. The result is a sleeker looking racing shell with improved performance.

Carbon Rigger: 2017

Sykes developed a new Bow mounted Carbon Fibre rigger for our single scull range. Starting with a target to be lighter and stiffer than the aluminium stern mounted rigger with backarms, the design evolved from the flat profile sections of the 1990’s rigger into a purpose designed shape that transfers the loads from the rower into the oar blade effectively.

Sykes developed a new Bow mounted Carbon Fibre rigger for our single scull range. Starting with a target to be lighter and stiffer than the aluminium stern mounted rigger with backarms, the design evolved from the flat profile sections of the 1990’s rigger into a purpose designed shape that transfers the loads from the rower into the oar blade effectively.

The customised shape provides very high stiffness under rowing loads as well as reduced vertical movement of the pin. This all results in greater power transfer into the water. Using substantial Finite element analysis and on-water analysis, we have been able to place carbon fibres in the right location and orientation to ensure highest efficiency and lowest weight. The new rigger will come in significantly lighter than the existing aluminium rigger (-600g+) as well as giving you a very direct feel when the catch is taking, propelling you to all new speeds.

Dedicated Single Sculls: 2016

Starting in 2015, Sykes endeavour to close the gap in the Single Scull market to have 5 dedicated moulds for five weight ranges of athlete. Designed to cover from 50-100kg, each hull is tailor designed to its weight class from an original hull surface. Designed in conjunction with Australian Athletes, Adelaide and Melbourne Universities, the hulls aim to maximise inherent stability in the hulls whilst minimising total surface area and narrow bows. This combination produces a stable, easy to row boat that has very low overall drag. Furthermore, each of our new Singles can be fitted with our new Carbon Fibre bow rigger.

Starting in 2015, Sykes endeavour to close the gap in the Single Scull market to have 5 dedicated moulds for five weight ranges of athlete. Designed to cover from 50-100kg, each hull is tailor designed to its weight class from an original hull surface. Designed in conjunction with Australian Athletes, Adelaide and Melbourne Universities, the hulls aim to maximise inherent stability in the hulls whilst minimising total surface area and narrow bows. This combination produces a stable, easy to row boat that has very low overall drag. Furthermore, each of our new Singles can be fitted with our new Carbon Fibre bow rigger.

Multiax CNC: Ongoing

Installed in October 2013, the Multiax CNC has redefined the innovation pathway leading to new products at Sykes. Paving the way for a fully digital development, our computer generated hull surfaces can now be cut out full scale in the CNC machine. This allows us to create plugs that are more accurate than ever before, ensuring the hard work in the hydrodynamic design stage heads out to the water next time you take your boat out.

Over the last few years, Sykes has taken on increasingly large amounts of mould manufacturing work using the 5 axis NC to produce complex patterns for all our customers. We have also been able to undertake projects in other industries including defence, automotive, construction, medical, solar technology and transport.

Advanced Fin Engineering: 2016

It has been clear to Sykes for many years that the standard rowing fin, a shaped piece of Aluminium, is not the ideal setup for a rowing shell, especially in small boats. Working with experts in Aerodynamics, with a history in Helicopter Blade design, and academics from the University of Melbourne, Sykes strove to redesign a Single scull fin to provide superior tracking for the stern, especially in cross wind and choppy conditions. The fin, designed through the use of extensive Computational Fluid Dynamics (CFD) was produced using Rapid Prototyping technology (3D printing).

After the initial CAD and CFD analysis, the fin was tested extensively on the water (on the windy Barwon and Mitchell rivers) and proved superior to the standard flat plate fin. However, the Sykes engineers were not satisfied and pushed to obtain objective data on the performance of the Fin. This was achieved through a joint partnership with Melbourne University towing tank. The fin was tested using a technique called flow visualisation, whilst being towed under a rowing boat in the Michelle Hydrodynamics Laboratory. This technique uses coloured dyes to produce visible streams of water highlighting the flow over the fin.

After the initial CAD and CFD analysis, the fin was tested extensively on the water (on the windy Barwon and Mitchell rivers) and proved superior to the standard flat plate fin. However, the Sykes engineers were not satisfied and pushed to obtain objective data on the performance of the Fin. This was achieved through a joint partnership with Melbourne University towing tank. The fin was tested using a technique called flow visualisation, whilst being towed under a rowing boat in the Michelle Hydrodynamics Laboratory. This technique uses coloured dyes to produce visible streams of water highlighting the flow over the fin.

From this, our engineers are able to decipher the conditions around the fin and the superiority of the Sykes developed fin over the standard flat plate aluminium fin. A very exciting development, Sykes continued to evaluate the performance of the fin using Minimax and Peach measurement systems on the boat, analysing the improvement in the boats yaw (turning left and right) when uneven inputs were applied (stronger rower on left or right sides, crosswinds, waves). The new fin performed superbly and is in the final stages of Development as of February 2017. Due for release in the Second half of 2017.

Finite Element Analysis: 2016

Using one of Australia’s most skilled Finite element analysis engineers, with over 20 years of experience in FEA, Sykes is continuing its work to make the most efficient use of carbon and other composite materials in our boats. By understanding the complex forces involved in the rowing stroke, we are able to place fibres in exactly the right place and orientation, ensuring a very efficient design, maximum stiffness and minimising weight. All this makes simply for a faster, stiffer boat.

Using one of Australia’s most skilled Finite element analysis engineers, with over 20 years of experience in FEA, Sykes is continuing its work to make the most efficient use of carbon and other composite materials in our boats. By understanding the complex forces involved in the rowing stroke, we are able to place fibres in exactly the right place and orientation, ensuring a very efficient design, maximum stiffness and minimising weight. All this makes simply for a faster, stiffer boat.

Hydrostatic Deflection Testing: 2016

To better understand the nature of how the boat moves under displacement (being submerged in water) as well as under athlete’s forces, Sykes has commissioned a project to measure static deflections of the hull. This will involve the accurate measurement of how much the hull moves when pushed downwards into the water, and will help us to understand the importance of athlete positioning to achieve a desired trim.

To better understand the nature of how the boat moves under displacement (being submerged in water) as well as under athlete’s forces, Sykes has commissioned a project to measure static deflections of the hull. This will involve the accurate measurement of how much the hull moves when pushed downwards into the water, and will help us to understand the importance of athlete positioning to achieve a desired trim.

Furthermore, in conjunction with advanced centre of mass movement patterns, it will allow us to optimise dynamic positioning of rowers and work one on one with our customers to make sure their boat setups allow them to maximise the hydrodynamic benefits of our racing shells. This project is being completed in conjunction with Australian Engineering Solutions (Austeng) and is a key project as part of our GRIF funding.

Rigger Bending Test

Every Sykes rigger is tested for its strength and its welds are inspected before it leaves the factory by our expert Metalshop, led by Darrell Smith. To further develop our aluminium and newly created Carbon Riggers, Sykes is commissioning a rigger bending testbed to test our riggers under a range of strenuous conditions. Designed to test the riggers under cyclical (resembling a rowers stroke) loads as well as high stress loads (i.e collisions), Sykes will work to produce even stronger and stiffer riggers than ever before. Looking to the future, Sykes hopes to revolutionise the boat/rigger connection to reduce the energy loss. Working with Australian Engineering Solutions under the Geelong Regional Investment Fund (GRIF) grant, Sykes is excited to bring some new ideas for how riggers should perform to the rowing market

Advanced Engineering Centre: 2015 Onwards

In 2015, Sykes worked to establish an Advanced Engineering Centre to tackle all product development processes for the company. In conjunction with the Geelong Regional Investment Fund (GRIF), Sykes invested heavily to expand its capabilities with increased resources to tackle even more work both in rowing and other fields. Over the last two years, Sykes has worked to streamline and develop an efficient product development pathway. At the current time, Sykes has a greatly expanded capability to conduct the 9 stage boat development pathway in-house, leading to shorter lead times and higher quality products. Furthermore, with the expansion of its engineering abilities, Sykes has been able to take on more external projects for clients such as Riviera Marine and Kerfton Camper Trailers.

Sykes now employs a team of dedicated engineers, CAD designers, Finite element analysis experts and some of Australia’s finest carbon fibre production staff. Combined with a production floor with skills in carbon, Kevlar and composite materials, a dedicated metal shop with skills in steel and aluminium, we can now produce prototypes and advance designs faster than ever before, leading the way in innovations.

Collaboration with University Research Projects: 2015 Onwards

Over the last twelve months, Sykes has strived to increase its collaboration with University research projects based in fields of interest for Sykes. In 2015, Sykes joined forces with Masters of Mechanical Engineering Students at Melbourne University to develop a drag measurement system for a single scull in the field. This project aimed to be able to identify whether real world measurements could be made accurately enough to measure drag resistance forces on a 70kg simulated athlete in a Sykes single scull. The initial design project produced successful testing results for a range of simulated athlete weights and speeds, and Sykes is working to continue the development of this first of its kind measurement system, helped by funding from the GRIF grant.

Spectra Steering: 2013

Our spectra steering system has replaced stainless steel wire and has had great results in the market. It features a much lighter weight mechanism without any corrosion issues arising from use in salt water. Now the cox, or steerer, has no excuses.

The Xouris Range: 2012

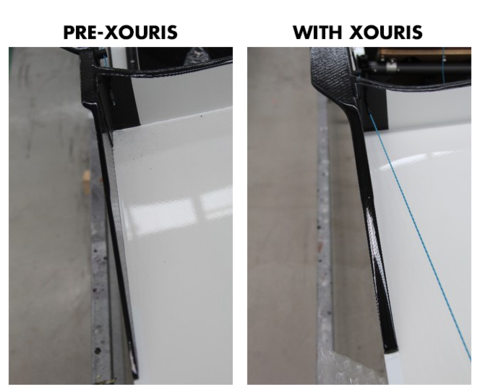

The Xouris range of boats represents a leap forward in technology that applies across all the boat ranges. Named after George Xouris who managed to win national titles in every event, the technological leap means that the thickness of the boat now varies. As you can see in the images below the thicker section at the top provides greater strength where it is required. Not only is it stronger, it also means that less material is used elsewhere saving weight where we can! Just like George this design evolution is a winner in any category.

To understand what sort of impact this has had on various boats the two photos below show a boat without Xouris and a boat now with Xouris construction.

There are plenty more innovations we create every day and our friendly sales team are always happy to discuss these further with you.